Structural Health Monitoring

• Bridges

• Tunnels

• Buildings

• Railroads

Condition Monitoring of wind farms

• Blade damage detection

• Ice detection

• Gearbox monitoring

• Foundations monitoring

• Lifetime prediction

Condition monitoring of industrial assets

• Circuit breakers

• Steel & glass furnace

• Overhead cranes

• Cryogenic installations

• Condition rotating equipment

Fiber optic FBG sensors are capable of capturing data at multiple point along a large structure, measuring strain as small as 1µƐ up to more than 5000µƐ, temperatures up to 1000°C, near DC and high frequency vibrations as well as current, tilt, displacement and more…

FBG sensors outperform electrical sensors in harsh environments

Fiber optic FBG sensors are ideally suited for demanding industries. They outperform electric sensors in environments with extreme temperatures, corrosion, electromagnetic interference and are safe to use in explosive applications.

Insensitive to electro-magnetic interference in motors, transformers, circuit breakers and cable termination

Resistant to corrosive environments in chemical processes or salt water in off-shore

Unaffected by lightning strikes on wind turbine blades or arcs in electric substations

Safe to use in explosive environments such oil & gas and hydrogen vessels

The unique advantages of our FBG interrogators

While fiber sensors are versatile, accurate and affordable, interrogators can be expensive. Thanks to its silicon photonics chip Sentea offers widely interoperable, reliable and cost-effective interrogators, enabling FBG fiber sensing for large scale deployment.

Interoperable

Compatible with most FBG sensing fibers and FBG strain, temperature, vibration and other sensors.

Reliable measurements

Patented polarization scrambler and temperature control features offer remarkable short and long-term acquisition accuracy & stability.

Edge computing

Featuring standard data interfaces and an open customer application platform for seamless integration.

Cost-effective

Our silicon photonics chip makes fiber optic sensing affordable and deployable at large scale.

Product Specifications

| Sentea interrogator | |||

|---|---|---|---|

| Number of fibers | |||

| Max. number of sensors per fiber (1) | |||

| Max. sampling frequency (2) | |||

| Wavelength range | |||

| Wavelength sensitivity (3) / Wavelength accuracy (4) | |||

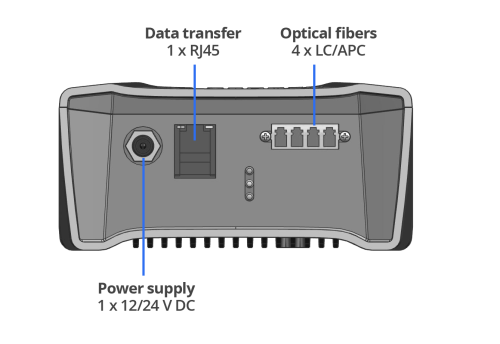

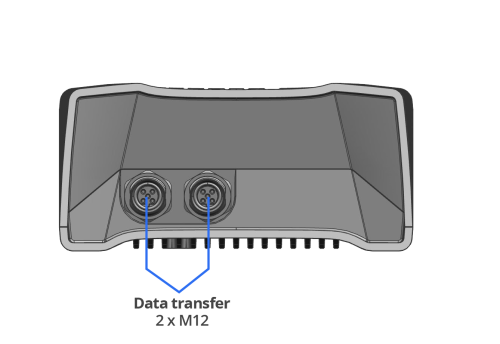

| Data interface | |||

| Software interface | |||

| Dimensions / Weight | |||

| Operating conditions (non-condensing) | |||

| List price (5) / lead times (6) | Starting at 2,750 EUR / 4 weeks |

||

(1) Minimum peak spacing of 1.6nm up to 2kHz or 3nm above 2kHz required in operation | (2) Valid for 1 fiber connected. For n fibers connected, this value has to be divided by 2n | (3) Defined as standard deviation over 10 minutes | (4) Over full temperature range | (5) Sentea general sales conditions apply | (6) Applies for small quantities, for larger quantities please contact us.

Would you like to learn more?

Our application engineers will be happy to tell you more about FBG fiber sensors. They can help you to find the right sensors for your sensing or monitoring application, explain how to interface with your systems and software, or prepare a customized quotation. Complete the contact page below and an application engineer will contact your shortly.

"*" indicates required fields