Learn more about fiber optic sensing, from multi-point and multi-parameter fiber sensors, over intelligent sensor data interpretation, to interfacing with control systems and monitoring rooms.

Reliable sensors for every application

Embedded sensing fibers

Use them to measure load, torque, temperature, shape or pressure. These fibers come pre-installed on steel or composite subsystems such as bearings, blades, storage vessels and tanks.

Fiber sensors

These sensors measure strain, temperature, acceleration as well as tilt and displacement. They can be welded, glued or secured with screws and magnets, ensuring easy installation.

Sensing patches

Suitable for measuring strain or temperature. They are easy to install and can be glued to flat or curved surfaces.

Continuous sensing along large structures with a single fiber

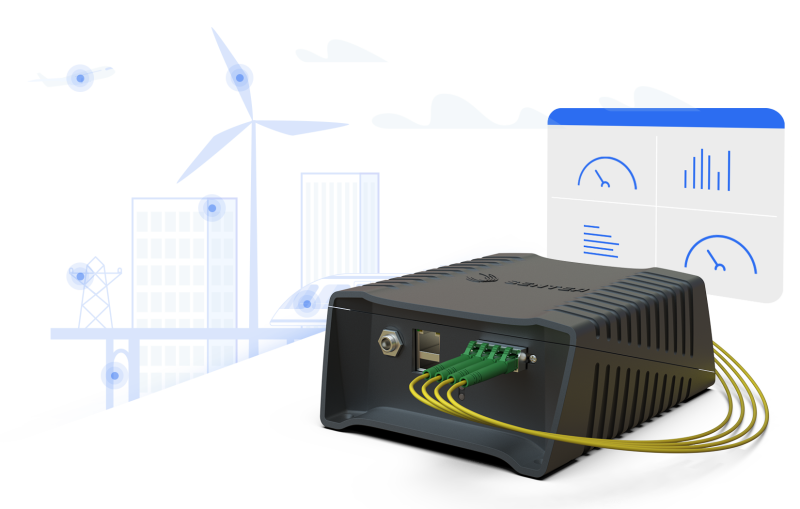

High speed and high volume data acquisition

They owe their exceptional compactness to silicon photonics, a technology that allows us to integrate all optical functions onto a single chip.

Silicon photonics has been used in telecom and datacom applications for more than a decade now and is gradually replacing older bulk optics in all photonics applications thanks to its scalability and low cost, using the same fabrication processes as electronic chips.

The right data, wherever you want it

Moreover, thanks to edge computing, our interrogators can already independently pre-process part of the massive amount of data that is gathered.

Want to talk about your monitoring needs?

Our sales engineers can answer any questions you may have.